Tools & Die Maintenance

Refurbishment, repair, and upkeep of dies to extend life and reduce downtime.

Tools And Die Maintanance

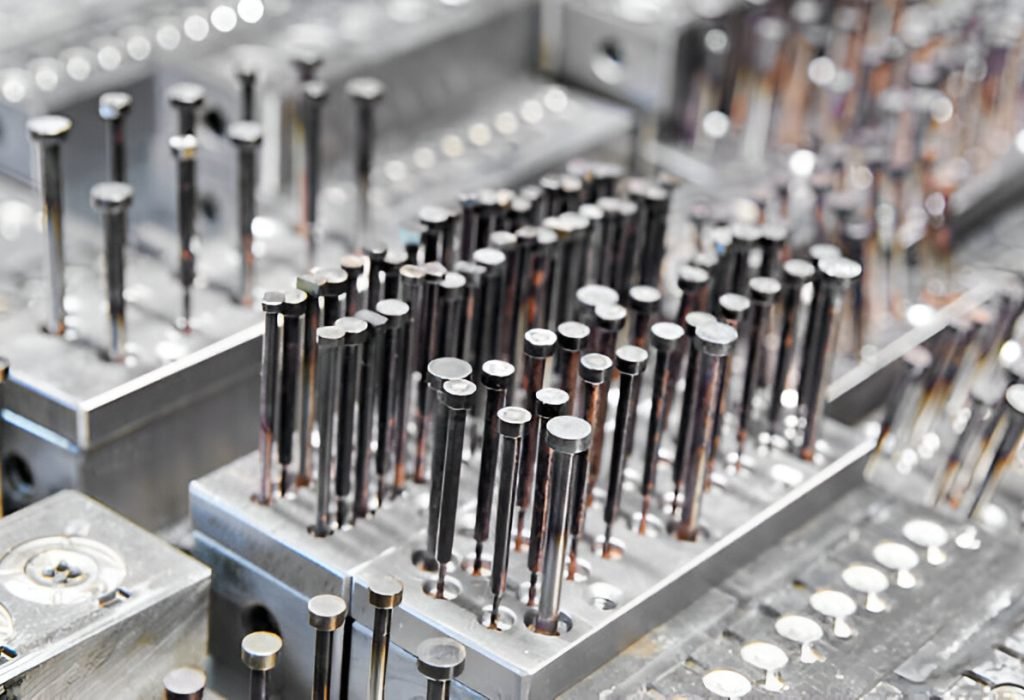

Tools and Die Maintenance is a crucial service in the die casting industry that ensures the longevity, efficiency, and precision of die-casting tools and equipment. At MAS Die Casting Pvt. Ltd., regular maintenance and upkeep of dies are carried out to avoid production delays, enhance tool performance, and maintain product quality. This includes activities like stress relieving, which helps in reducing internal stresses in the die; polishing to maintain the smoothness and finish of the die surface; and gas nitriding for surface hardening to improve wear resistance. Advanced coatings like Balzer Coating are applied to extend tool life, while critical replacements such as ejector pins and component pins are done to maintain optimal functionality. Lapping, a precision process, is used to ensure flatness and proper alignment. Detailed records of each die’s maintenance history are also maintained to support proactive servicing and efficient die management. This ensures consistent quality and minimizes downtime in manufacturing processes.

Tools and Die Maintainance Services

Reliabillity

Ensures the consistent Die Operations.

Expertise

Skilled in handling various Die Types.

Quality Care

Pays attention to every detail.

Extensive Capabillities

Addresses a wide range of needs.

Our Tools And Die Maintainance Methods

Stress Reliving

Polishing

Gas Nitriding

Balzer Coating

Ejector Pins Replacement

Component Pins Replacement