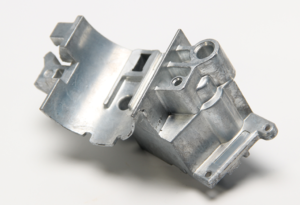

Precision in Every Cast

global industries.

About Us

Mas Die Casting Pvt. Ltd. is a trusted expert in Aluminium & Zinc high-pressure casting dies and components. With over 22 years of experience, we provide end-to-end solutions—from conceptualization to production—ensuring top-tier performance, cost-effectiveness, and quality. Recognized as one of India's best-equipped pressure die casting facilities, we are IATF 16949-2016 & ISO 9001 certified and backed by a skilled workforce of 300+. Our state-of-the-art technology and in-house expertise enable us to tackle complex industrial requirements with precision. We specialize in delivering high-quality, reliable products for OEMs, working closely with design specialists to optimize outcomes at minimal cost. At MAS, we integrate value-added engineering to exceed expectations in every project.

Products

Automotive Components

Non Automotive Components

Medical Equipment Components

Home Appliance Components

Electrical Equipment Components

Power Tool Components

Our Services

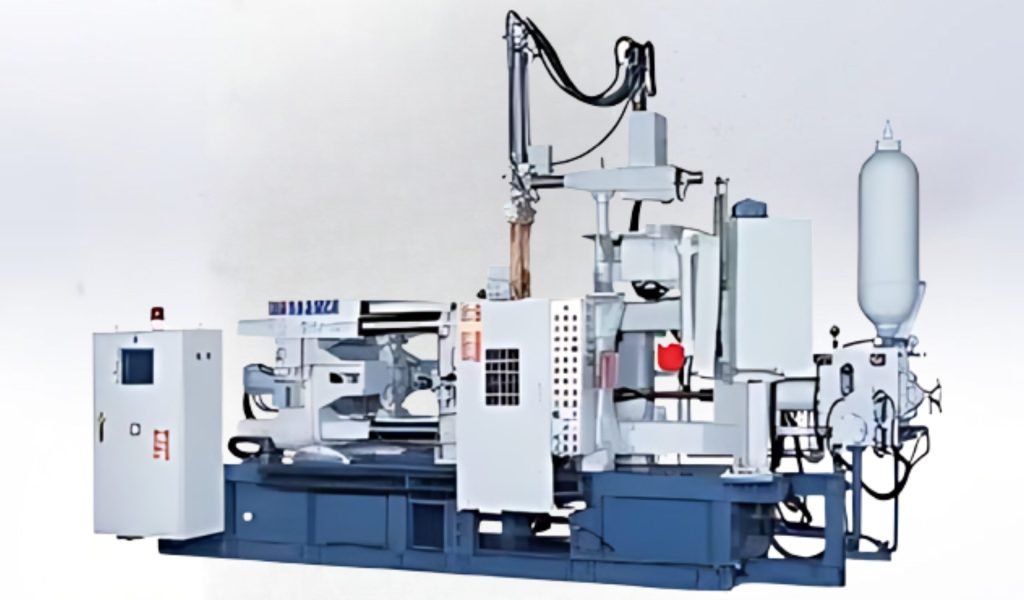

The art of casting metal under pressure and temperature runs in our veins. Our love for high-pressure die casting.

As a company that prides itself in providing our customers the best service and support.

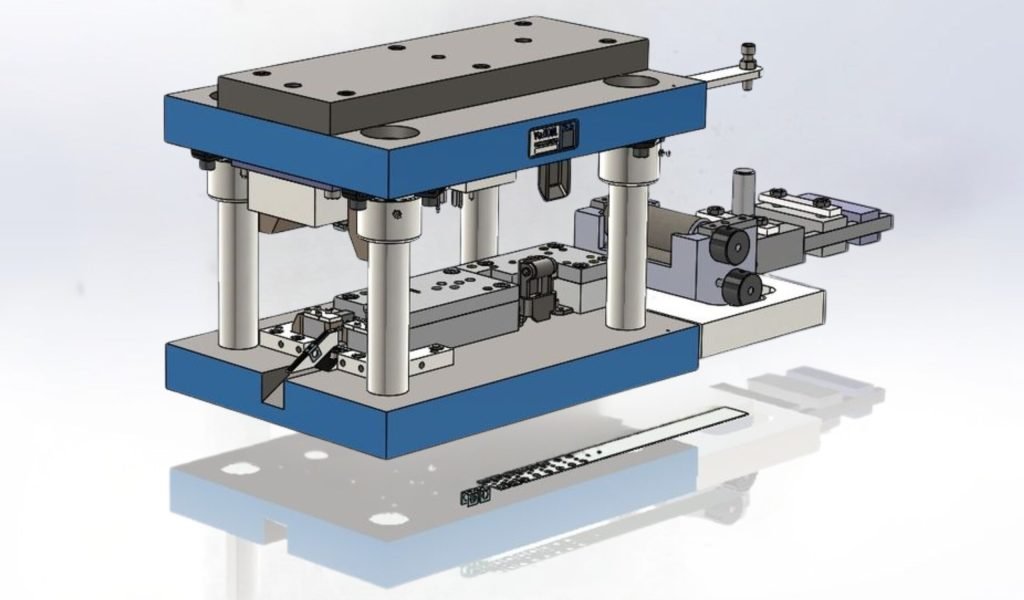

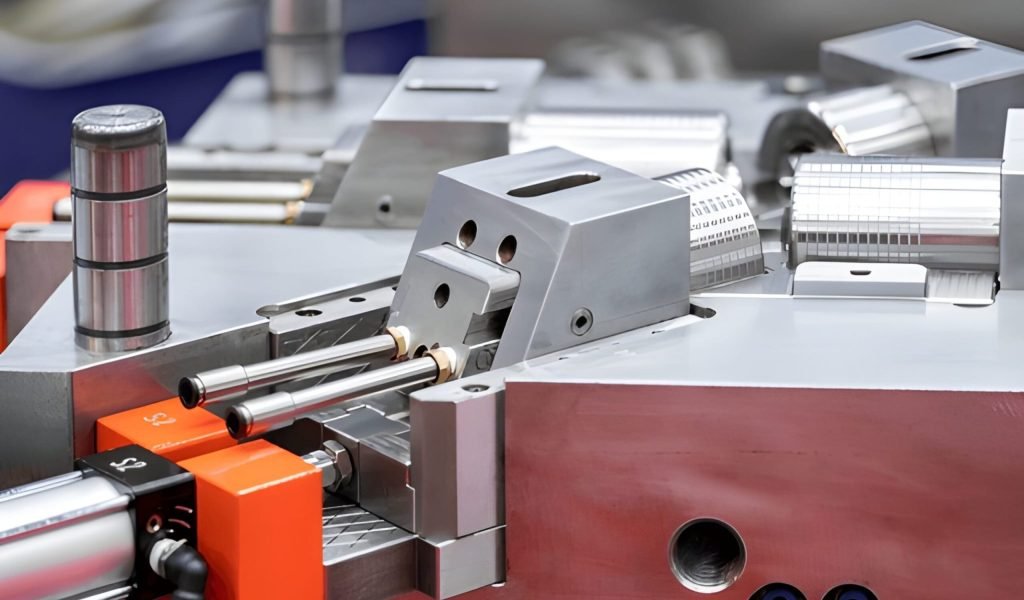

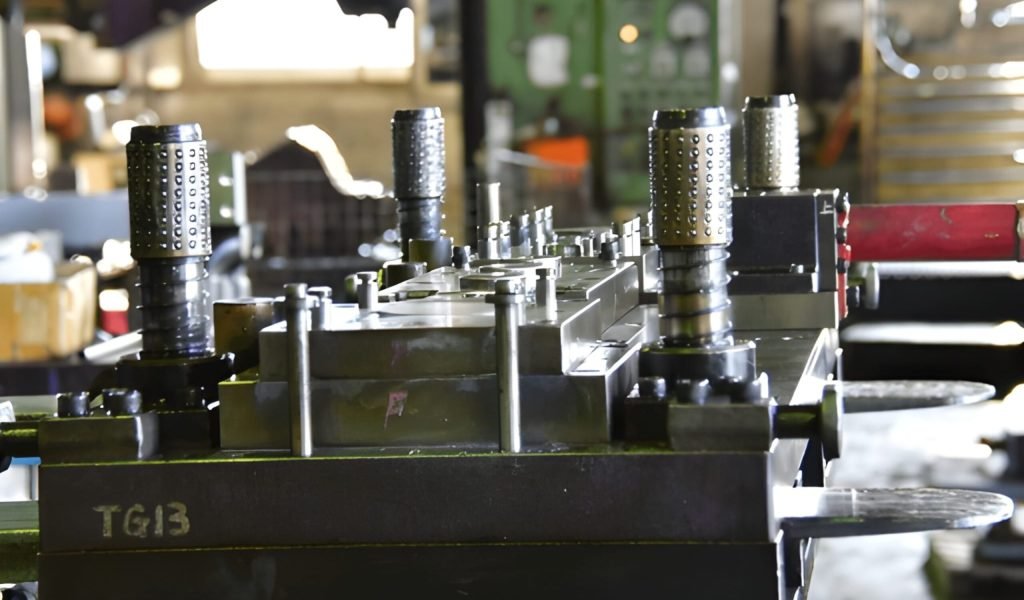

Die Making is the process of designing and manufacturing specialized tools called dies that are used to shape.

Mas Die Casting Offers a range of Component finishing, which refers to the processes used to modify the surface of a manufactured part.

Component Treatment refers to a group of processes used to enhance the surface, durability, appearance.

In die casting, testing and inspection are crucial steps to ensure the quality and reliability of the final product.

Tools and Die Maintenance is a crucial service in the die-casting industry that ensures the longevity.

customers in India and abroad. We have been certified with ISO 9001: 2000 that assure for better quality of each of our plants.

Why Choose Us ?

At MAS DIE CASTING PVT LTD, we are more than just a die casting manufacturer . we are your complete aluminium casting solution partner, With everything under one roof. We offer unmatched efficiency, precision, and reliability for all your casting needs.

From product design and die development to casting, CNC machining, finishing, and quality testing we manage every step in-house to ensure full control over quality and timelines.

Quality is at the core of everything we do. Our processes are backed by rigorous quality checks, advanced inspection tools, and a skilled quality assurance team to ensure defect-free components every time.

Our facility is equipped with the latest high-pressure die casting machines, automation systems, CNC and Vmc technology, allowing us to produce high-precision parts at competitive costs.

With more then 25 years of experience and a dedicated team of engineers and technicians, we understand the technical and commercial requirements of various industries automotive, electrical, Home appliances, Medical equipment and more.

Custom Solutions

We don’t believe in one-size-fits-all. We work closely with each customer to deliver customized casting solutions, whether it’s a complex part or a high-volume order.

We know how important timelines are. Our streamlined operations and strong project management ensure timely delivery without compromising quality.

We are committed to environmentally responsible manufacturing, using energy-efficient equipment, minimal waste processes, and recyclable materials wherever possible.